Zaverl Hall

Baran Drive Southeast, Lacey

WA 98503

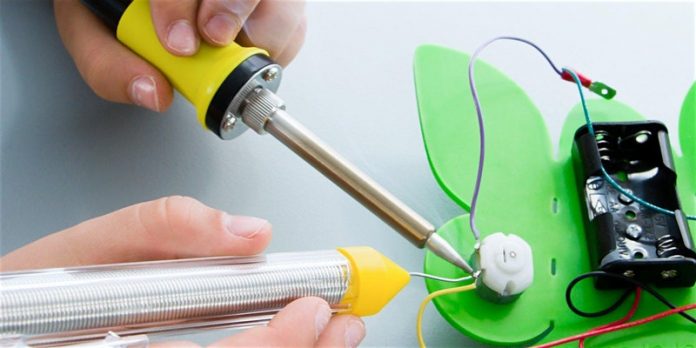

Soldering is one of the basic skills of repair. Hammering is a basic skill of wood working, wrenching is a basic skill of mechanical repair, and soldering is a basic skill of electrical repair. Learn these basics and you have some idea how to attack just about any repair problem. When you can fix things, you get confidence. I often see people panic when stuff breaks (like cars, computers, etc.). They feel at the mercy of their mechanic, electronic salesman, etc.. Knowing how stuff is made or repaired give self confidence. Soldering is small part of understanding but it is an entry point to understand these things.

Being able to solder is a critical skill everyone interested in electronics should have. It is the only way to move beyond merely plugging in shields to an Arduino. Protoboards, alligator clips, and twisted wires are OK for developing a project, but too unreliable to count on.

Supplied: Soldering stations, solder, wire cutters, well-lit workspace.

Students will leave with: Safety glasses, solder, two electronic kits.

Requirements: Long sleeve shirt, long pants, preferably 100% cotton. Bring whatever aids you need for close work.

Class length: Four hours with breaks

Hour one: What is soldering for, how does it differ from brazing and welding? Types of solder, types of flux. Different types/classes of soldering irons and stations and what to look for to get a good soldering iron. What to avoid in a soldering iron. What is reflow soldering? Lead-tin vs lead-free solder. Prerecorded and live demonstrations of soldering. Review Safety Rules for Soldering. Live and prerecorded demos including connectors and splicing.

Hour two: Go over answers to Safety Rules for Soldering. Get your first kit and safety glasses. A quick review of principles and demo to remind everyone of the proper pacing and techniques. Speak on how to determine the order of components, and the order of solder joints. Have everyone solder five connections on their kit PCB, then inspect. Help those who need it, have everyone continue soldering. Inspect everyone’s kits for proper placement, solder joints, polarity of components, and for solder bridges.

Hours three and four: Inspect work so far. Demonstrate soldering connectors on cables. Should you solder crimp connectors and wires inserted in terminal blocks? Demonstrate desoldering techniques; desolder braid, solder sucker, ChipQik low temperature, hot air. Get your second kit and begin soldering.

Some soldering stations may be available for purchase after the class.